Many users often neglect replacing the sealing rings in pressure cookers until leaks, insufficient pressure, or even safety hazards occur. Linkton, combining industry standards and our expertise, provides a comprehensive analysis of the causes of pressure cooker sealing ring aging, replacement signals, recommended replacement cycles, and practical tips for extending its lifespan, helping you use your pressure cooker safely and efficiently in commercial kitchens or at home.

4 Reasons for Regular Pressure Cooker Sealing Ring Replacement

Material Aging and Loss of Elasticity

- High-temperature hardening: Prolonged exposure to temperatures above 100°C makes silicone hard and brittle. Elasticity decreases by 50%, compromising sealing.

- Permanent Deformation: Continuous pressure causes plastic deformation, significantly reducing rebound capability.

Declining Sealing Performance

- Pressure Leakage: Aged rings prevent the cooker from reaching the rated working pressure (e.g., 80 kPa).

- Energy Waste: Poor sealing leads to heat loss, resulting in an increase by over 30% in energy consumption.

Health Hazards

- Bacterial Growth: Food residues trapped in ring crevices become breeding grounds for bacteria (65% of tested rings exceed bacterial standards).

- Odor Absorption: Porous structure easily absorbs food odors, affecting taste.

Safety Risks

- Sudden Pressure Release: Aged rings may fail during cooking, causing steam.

- Unstable Pressure: Poor sealing leads to excessive pressure fluctuations, compromising both cooking and safety.

Warning Signs of Ring Aging

- Hardening and Brittleness: No elasticity when pressed

- Visible Deformation: Does not maintain a circular shape when placed flat

- Color Change: White rings turn yellow; colored rings fade

- Cracks Appear: Microscopic surface cracks

- Persistent Odors: Food smells remain after cleaning

Recommended Replacement Cycle

| Usage Frequency | Replacement Cycle | Abnormal Signs |

| Daily Use | 68 months | Hardening/deformation |

| 34 Times/Week | 12 months | Reduced sealing |

| Occasional Use | 18 months | Cracks/odors |

| Commercial Use | 34 months | Any visible damage |

3 Key Steps for Replacement

Step 1:Proper Removal

- Operate after complete cooling

- Gently pry the old ring from the groove

- Clean food residues from the installation slot

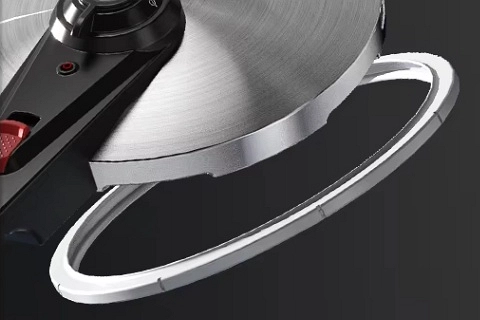

Step 2: Installing a New Ring

- Ensure exact model matching

- Evenly embed into the groove

- Ensure full circumferential seating

Step 3: Seal Testing

- Test sealing with an empty cooker heating

- Check for steam leakage

- Confirm normal pressure buildup

Replacement Costs by Brand

| Brand | OEM Ring Price | Compatible Part Price |

| Liantong | $35 | $24 |

| Fissler | $1218 | $69 |

| WMF | $1015 | $58 |

| Supor | $34.5 | $1.53 |

5 Tips to Extend Pressure Cooker Sealing Rings’ Life

- 1. After Each Use: Wipe clean with a soft cloth and air dry

- 2. Weekly Deep Clean: Disinfect with diluted white vinegar

- 3. Proper Storage: Remove the ring for storage to avoid constant pressure

- 4. Avoid Oil Corrosion: Keep away from strong acids/alkalis

- 5. Regular Lubrication: Food-grade silicone oil, quarterly

Special Reminders

- Don’t PennyPinch: A $3 ring may prevent thousands in medical costs!

- No Substitutes: Never use alternative materials

- Stop Immediately: Discontinue use if the ring shows problems

Conclusion

The sealing ring is the “gatekeeper” of your pressure cooker. Regular replacement is essential not only for cooking performance but also for family safety. Check the ring status during each cleaning and replace promptly if needed. As a professional stainless steel pressure cooker manufacturer, Linkton always adheres to safety and quality as the core, providing customers with high-standard pressure cooker solutions. If you encounter any problems during the use or replacement of the pressure cooker sealing ring, please feel free to contact us.

Sources:

- 1. National Kitchenware Quality Testing Center

- 2. “Pressure Cooker Safety Usage Standards”

- 3. International Food Safety Association