Pressure cookers are essential kitchen appliances with consistently growing demand worldwide. Many overseas brands, importers, and distributors seek OEM pressure cooker solutions to develop high-quality stainless steel pressure cookers under their own brand.

However, purchasers often face several critical challenges when sourcing from OEM manufacturers:

- What if the prototype works perfectly, but mass production differs?

- Is the MOQ (Minimum Order Quantity) feasible for small-scale testing?

- How to mitigate production delays or quality inconsistencies?

- How to protect mold ownership and intellectual property?

In this article, Linkton provides a practical guide for overseas purchasers, explaining the OEM process from prototype design to mass production while highlighting risk management and verification methods.

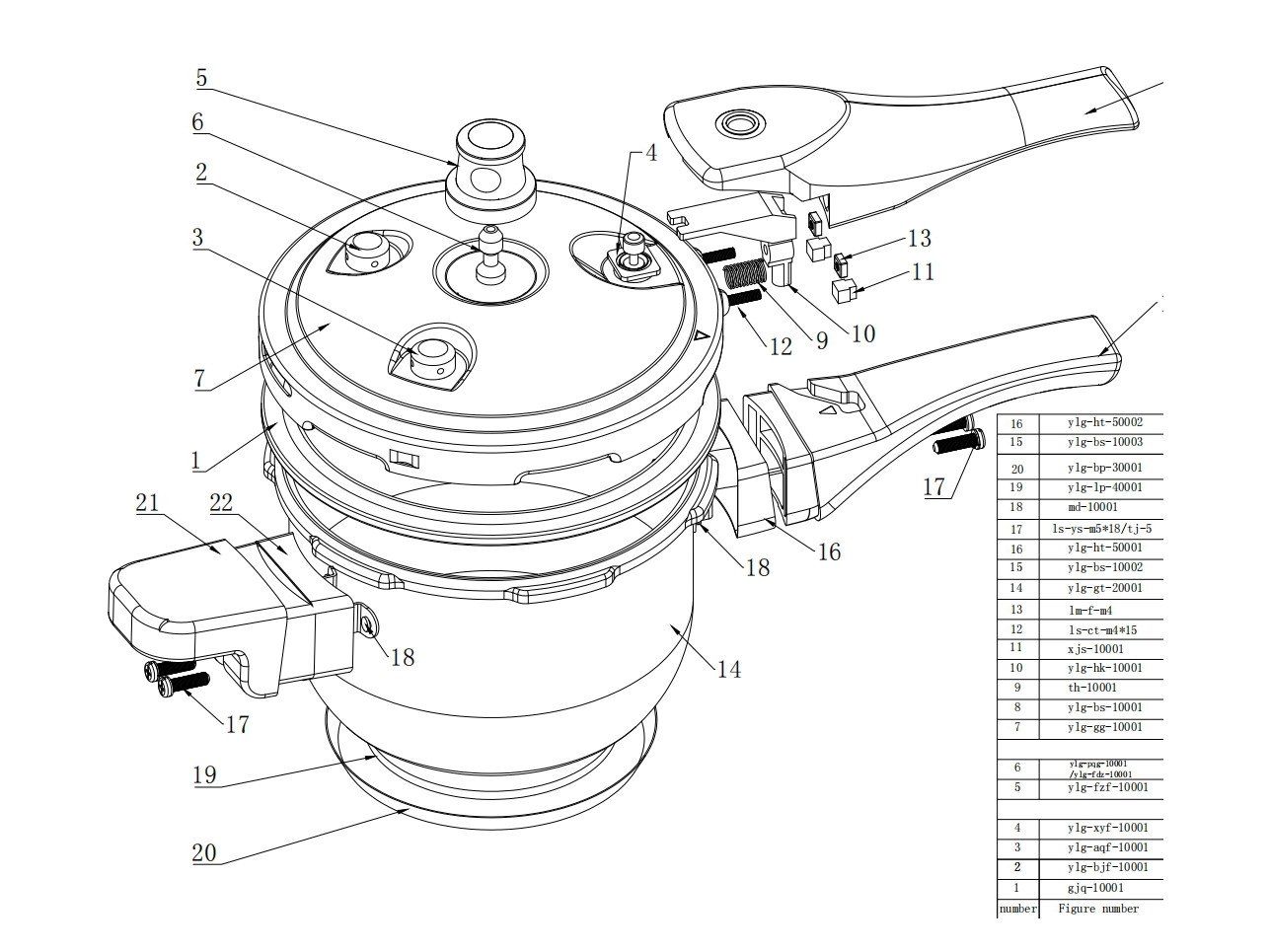

Step 1: OEM Pressure Cooker Prototype Design Stage

The first step in OEM production is prototype development. Buyers provide product concepts, capacity, functionality, and appearance requirements, and the manufacturer evaluates feasibility.

Key Actions & Recommendations

Feasibility Assessment

- Material selection (304/316 stainless steel), production technology, and compliance with certifications (CE, FDA, LFGB)

- Achievable pressure, sealing, and valve performance

- Cost feasibility to prevent overly complex prototypes that inflate production costs

Prototype Production

- CNC stamping, hand welding, or 3D printed models

- Stainless steel thickness is usually 0.5–0.8 mm, with multilayer composite bottoms for even heat distribution

Prototype Testing & Iteration

- Sealing Test: Pressure maintained for 3 minutes, pressure drop ≤5 kPa

- Safety Valve Test: Response time <0.5 seconds

- Functional testing: capacity, lid sealing, ease of use

- Typically, 2–3 rounds of iterations to optimize performance and aesthetics

Purchase Tip: Request test videos, material certifications, and valve calibration records from suppliers. Consider hiring an independent engineer to verify prototype reliability.

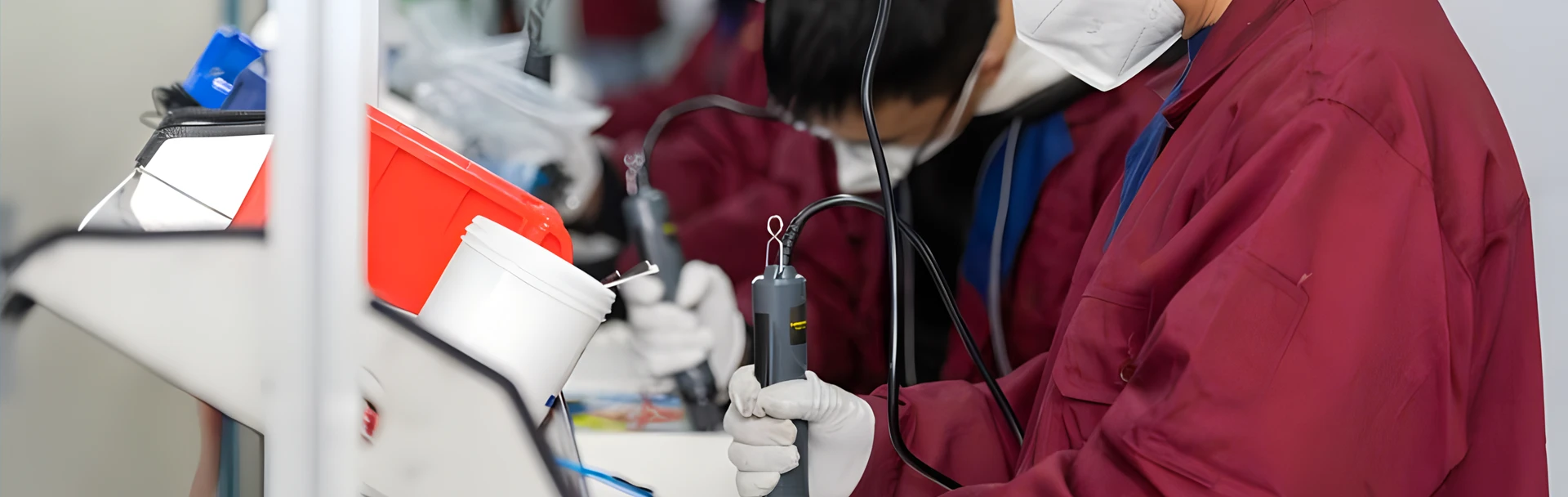

Step 2: Pressure Cooker Pilot Production (Small Batch Trial)

After prototype approval, a pilot production batch verifies production line stability and consistency.

Practical Considerations

Batch Size & Timeline

- Usually 200–500 units, covering different capacities or features

- Timeline: 2–4 weeks, adjustments made based on buyer feedback

Automated Production & Quality Control

- Robot Welding: Ensures uniform welds

- CNC Stamping & Polishing: Dimensional accuracy ±0.1 mm

- Online Pressure Testing: Checks working pressure and valve performance

- Material Verification: Random inspection of 304/316 stainless steel thickness and composition

Buyer Validation

- Inspect sealing, pressure, valve responsiveness, and appearance

- Independent third-party inspection is recommended for added assurance

Purchaser Tip: Use pilot production to confirm prototype-to-mass production consistency. Keep detailed documentation for contract references.

Step 3: Pressure Cooker Mass Production Stage

Once the pilot batch is approved, mass production begins. This stage demands high-quality control and supply chain management.

Key Control Measures

Material & Component Management

- 304/316 stainless steel, multi-layer composite bottoms

- Certified components (valves, handles) complying with CE/FDA/LFGB

Production Line & Quality Assurance

- Automated lines for welding, stamping, polishing, and assembly

- 100% pressure testing and automatic valve calibration

- Appearance, polish, and packaging inspections

Consistency & Delivery Management

- Batch QC reports provided

- Standard lead time: 30–45 days, subject to material availability, complexity, and peak season

- Contracts should include provisions for delays and remedies

MOQ & Cost Management

- Standard orders: 500–1000 units

- Small brands can reduce initial MOQ via shared molds or split orders

- Cost components: mold, material, certifications, shipping, and optional custom functions

B2B Buyer Tip: Request batch inspection reports, production photos/videos, and third-party mid-production inspection to ensure consistency with approved samples.

4. Key Considerations When Selecting an OEM Pressure Cooker Manufacturer

Verification of Credentials

- ISO9001, CCC, and other certificates; verify authenticity

- Export certifications (CE, FDA, LFGB) for smooth customs clearance

- Check export data, client references, and conduct video factory audits

Contracts & Intellectual Property Protection

- Specify mold ownership, IP rights, quality standards, and penalties

- Include AQL (Acceptable Quality Level), payment terms, and delivery clauses

Third-Party Inspection

- Recommended both mid-production and pre-shipment

- Inspect pressure, sealing, valve performance, appearance, and packaging

Supply Chain Resilience

- Verify material stock, backup production lines, and contingency plans

About Linkton, Reliable Pressure Cooker with OEM Capabilities

As a leading stainless steel pressure cooker manufacturer, Linkton offers a complete OEM pressure cooker solution for global purchasers:

- Full process support: from prototype, pilot production to mass production

- Provides international certifications and batch quality inspection records

- Offers customizable functions, private labeling, and packaging

- Sample iterations and engineering support help brands reduce mass production risks

Note: Purchasers should still combine independent inspection and solid contracts.

Conclusion

OEM pressure cooker production involves multiple critical stages. Buyers should focus on:

- Prototype Stage: Confirm feasibility, material safety, and functional reliability; iterate as needed

- Pilot Production: Verify manufacturing processes and consistency; consider third-party inspection

- Mass Production: Ensure batch consistency, delivery timelines, and supply chain robustness

- Contracts: Clearly define quality standards, IP rights, and penalties for breaches

- Cost & MOQ: Understand all cost components; explore shared molds or split orders to lower entry barriers

Procurement decisions should be based on data, standards, third-party verification, and contractual safeguards, not solely on supplier marketing claims. Linkton’s practices can serve as a reference to help brands launch reliable, high-quality pressure cookers. If you need OEM pressure cookers, feel free to contact us; we are ready to provide high-quality stainless steel pressure cookers wholesale and bulk orders.