Pressure cookers have become an essential appliance in kitchens and the foodservice industry worldwide. For overseas importers and brand owners, sourcing high-quality, durable, and safe pressure cookers is crucial. In recent years, multi-layer composite bottom pressure cookers have emerged as the preferred choice among importers and wholesalers. In this article, Linkton will explain why these cookers are favored, focusing on technical advantages, purchasing value, and Linkton’s manufacturing capabilities.

Technical Advantages of Multi-Layer Composite Bottom Pressure Cookers

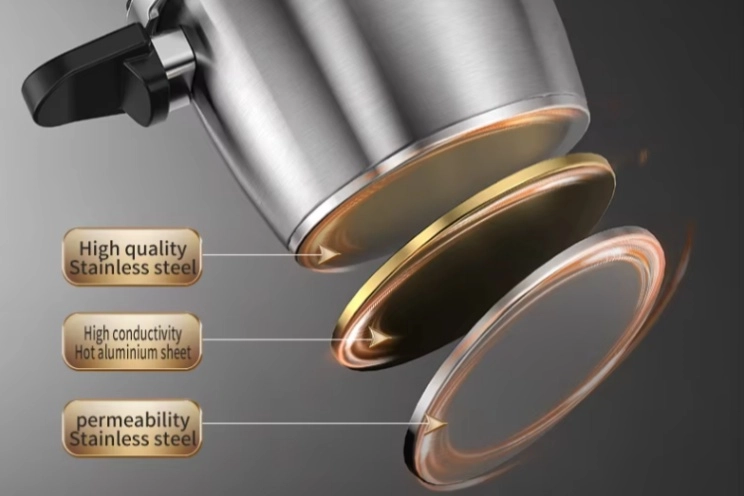

Even Heat Distribution

The multi-layer composite bottom design combines stainless steel with aluminum or copper layers to achieve uniform heat distribution, preventing hot spots and sticking. For importers, this ensures consistent cooking performance for end consumers and adds strong selling points for private label pressure cookers.

Anti-Deformation and Durability

Traditional pressure cookers may deform or warp after long-term use. Multi-layer composite bottoms effectively prevent these issues and extend the product lifespan. For stainless steel pressure cooker exporters, this reduces return rates and after-sales costs, offering higher procurement reliability for importers.

Scratch Resistance and Energy Efficiency

The composite bottom enhances scratch resistance and ensures rapid, even heat conduction, which also saves energy. For importers and B2B buyers purchasing in bulk, this design provides a balance between cost control and end-user satisfaction.

Multi-Layer Composite Bottom Pressure Cookers Purchasing Value for Importers

Reduced After-Sales Risks

The durability and stability of multi-layer composite bottom pressure cookers minimize quality issues during sales, lowering complaints and returns. For B2B buyers, this is a key factor when choosing high-quality pressure cookers.

Enhanced Market Competitiveness

In competitive export markets, importers sourcing multi-layer composite bottom pressure cookers can leverage superior performance and durability to strengthen their private label pressure cooker offerings and gain customer trust.

Cost-Effectiveness Considerations

Although multi-layer composite bottom pressure cookers may have slightly higher production costs, their durability and lower return rates make them cost-effective in the long term. This makes them ideal for importers seeking a stable supply and minimized procurement risks.

Linkton Manufacturer Manufacturing Advantages and OEM Capabilities

Materials and Manufacturing

- 304/316 medical-grade stainless steel ensures export-quality stainless steel pressure cookers meet international food safety standards

- Three-layer or five-layer composite bottom design achieves rapid heat transfer and long-term durability

- Precision CNC stamping and automated polishing guarantee a consistent appearance and feel across all units

Quality Control System

- Every pressure cooker batch undergoes pressure testing, sealing testing, and wear testing

- Complies with CE, FDA, and LFGB international certifications

- Ensures importers’ pressure cooker purchases are stable, safe, and reliable

OEM / ODM Customization

- Supports private label logos, packaging design, and functional customization

- Capacity, color, and accessory adjustments based on importer requirements

- Stable lead times for bulk orders, suitable for long-term B2B cooperation

Multi-Layer Composite Bottom Pressure Cookers Purchasing Tips for Importers

How to Choose a Multi-Layer Composite Bottom Pressure Cooker Supplier?

- Verify certifications such as CE, FDA, LFGB

- Check factory production capacity and quality inspection process

- Review OEM / ODM experience and export case studies

Usage and Maintenance Tips

- Regularly inspect sealing rings and safety valves to ensure proper operation

- Avoid dry heating and excessive high heat to extend lifespan

- Keep the bottom clean to prevent scratches or carbon buildup

Conclusion

Multi-layer composite bottom pressure cookers stand out for their even heat distribution, durability, and energy efficiency, making them the preferred choice for importers and brand owners. For B2B buyers, choosing high-quality pressure cookers not only reduces after-sales risk but also enhances market competitiveness and brand value. Linkton specializes in high-quality export stainless steel pressure cookers, offering multi-layer composite bottom pressure cookers with OEM/ODM customization services to support importers and brand owners with a stable and reliable supply. Contact us to request samples, pricing, and OEM customization options, and make your pressure cookers stand out in the international market.