La válvula de seguridad es el "corazón" de un olla a presióndirectamente relacionados con la seguridad de uso. Según las estadísticas, el 70% de los accidentes en ollas a presión están relacionados con fallos en la válvula de seguridad o con un mal uso de la misma. Este artículo ofrece un análisis en profundidad de las funciones de la válvula de seguridad de la olla a presión, los principios de funcionamiento y consejos de mantenimiento para ayudarle a dominar completamente este componente crítico.

Funciones principales de las válvulas de seguridad para ollas a presión

Regulación de la presión

Liberación automática de la presión: Cuando la presión de la olla supera el valor nominal (normalmente 80-100kPa), la válvula se abre automáticamente para liberar vapor.

Mantenimiento a presión: Mantiene la presión constante dentro de un rango seguro para garantizar una cocción uniforme.

Protección contra sobrepresión

Mecanismo antiexplosión: Actúa como última línea de defensa para liberar forzosamente la presión cuando el respiradero principal está bloqueado o la presión aumenta de forma anormal.

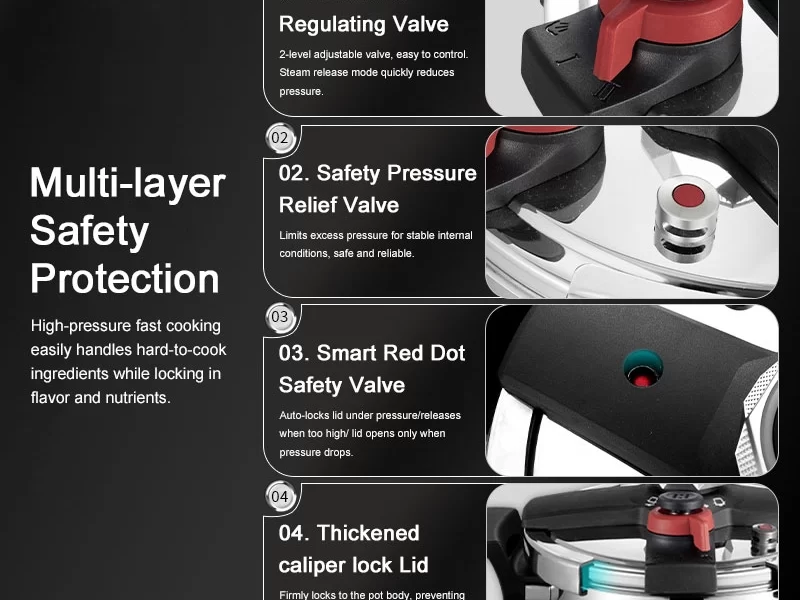

Diseño redundante: Ollas a presión de alta calidad (por ejemplo Linkton) están equipadas con válvulas de seguridad primaria y secundaria para mejorar la seguridad.

Indicación de estado

Señales visuales: Algunas válvulas de seguridad incorporan marcadores codificados por colores o diseños emergentes (por ejemplo, el sistema Vitavit de Fissler) para mostrar visualmente el estado de la presión.

Advertencias auditivas: Un silbido continuo indica una presión excesiva que requiere un ajuste térmico.

Cuatro tipos principales de válvulas de seguridad

Ollas a presión utilizan distintos tipos de válvulas de seguridad para lograr el control de la presión y la seguridad. La siguiente tabla resume los principales tipos, sus ventajas y limitaciones.

| Tipo | Principio de funcionamiento | Ventajas | Desventajas |

|---|---|---|---|

| Ponderado | Utiliza un peso para controlar la liberación de presión | Estructura sencilla, bajo coste | Requiere ajuste manual de la presión |

| Con muelle | Utiliza la tensión del muelle para controlar el funcionamiento de la válvula | Gran capacidad de respuesta y precisión | Los muelles son propensos a la fatiga y al envejecimiento |

| Tapón fusible | La aleación a baja temperatura se funde para liberar presión | Absolutamente fiable, sin fallos mecánicos | De un solo uso, requiere sustitución |

| Smart Electric | Sensor + control por microprocesador | Presión programable, ajuste automático | Caro, depende de la electricidad |

Hitos en la evolución tecnológica de las válvulas de seguridad

La evolución de las válvulas de seguridad ha visto hitos significativos: desde las primeras válvulas ponderadas en la década de 1930 hasta las modernas válvulas inteligentes habilitadas para IoT en la década de 2020.

1930s: Válvulas de seguridad ponderadas de primera generación (ollas a presión de aluminio).

1980s: Se popularizan las válvulas de seguridad accionadas por resorte, con una precisión mejorada hasta ±5kPa.

2000s: Sistemas de seguridad compuestos (por ejemplo, el diseño de liberación de presión cuádruple de Liantong).

2020s: Válvulas de seguridad inteligentes IoT (alertas Wi-Fi + funciones de apagado automático).

Perspectivas de las tecnologías de seguridad innovadoras

De cara al futuro, se espera que la tecnología de válvulas de seguridad integre soluciones más inteligentes y automatizadas para mejorar la seguridad de las cocinas y la eficacia operativa.

- Válvulas autolimpiantes: Tecnología de descalcificación por ultrasonidos (modelo conceptual Linkton 2024).

- Reconocimiento biométrico: Activación por huella dactilar + doble seguro para niños.

- Conectividad por satélite: Envía automáticamente señales de socorro en caso de sobrepresión extrema (modelos comerciales).

Comparación tecnológica de las válvulas de seguridad de marca

La siguiente comparativa ayuda a los operadores de cocinas comerciales a elegir la olla a presión más adecuada en función de su precisión, fiabilidad y comodidad de mantenimiento.

| Marca | Tecnología de válvulas de seguridad | Respuesta Precisión | Características especiales |

|---|---|---|---|

| Fissler | Sistema de presión constante Vitavit | ±2kPa | Indicador visual de presión |

| Likton | Diseño redundante de doble muelle | ±3kPa | Filtro antiobstrucción + limpieza desmontable |

| Olla Instantánea | Electroválvula | ±1kPa | Control de la presión APP |

| ZWILLING | Válvula de seguridad Cool-Touch | ±4kPa | La válvula permanece fría al tacto |

Preguntas frecuentes sobre la válvula de seguridad de las ollas a presión (FAQ)

P1: ¿Es normal que salgan restos de comida por la válvula de seguridad?

Contesta: Anormal. Indica un filtro a prueba de obstrucciones defectuoso o un exceso de ingredientes alimentarios. Deje de usarlo inmediatamente y límpielo.

P2: ¿Con qué frecuencia deben sustituirse las válvulas de seguridad?

Contesta: Las válvulas de muelle deben sustituirse cada 2-3 años; los tapones fusibles deben cambiarse después de cada fusión; los tipos eléctricos requieren mantenimiento según el manual.

P3: ¿Puedo desmontar yo mismo la válvula de seguridad?

Contesta: Sólo para diseños desmontables (por ejemplo, el tipo twist-off de Liantong). La mayoría de las marcas recomiendan el mantenimiento en fábrica.

Conclusión:

Las válvulas de seguridad son algo más que simples componentes; son dispositivos esenciales que protegen tanto el entorno de la cocina como a los operadores. A la hora de elegir una olla a presión, priorice:

- Diseño de seguridad multiredundante (por ejemplo, válvulas primarias y secundarias).

- Estructura de fácil desmontaje y limpieza (evita la acumulación de incrustaciones a largo plazo).

- Asistencia posventa de la marca (garantizar la disponibilidad de piezas).

Como fabricante profesional de ollas a presión, Linkton ofrece productos de válvulas de seguridad multitipo de alta precisión, seguros y fiables, así como servicios personalizados, y se compromete a proporcionar un suministro estable y asistencia técnica a los clientes de catering y cocinas comerciales. Bienvenido a Contacto!