安全弁は、安全弁の "心臓 "である。 圧力鍋使用上の安全に直接関係する。統計によると、圧力鍋の事故の70%は、安全弁の故障または誤用に関連しています。この記事では、圧力鍋の安全弁の機能、動作原理、およびメンテナンスのヒントを徹底的に分析し、この重要なコンポーネントを完全にマスターするのに役立ちます。

圧力鍋用安全弁の中核機能

圧力調整

自動圧力解放: ポットの圧力が定格値(通常80~100kPa)を超えると、バルブが自動的に開いて蒸気を放出する。

圧力メンテナンス: 安全な範囲内で圧力を一定に保ち、均一な調理を実現。

過圧保護

爆発防止メカニズム: メインベントが遮断されたり、圧力が異常に上昇した場合に、圧力を強制的に逃がす最後の砦として機能する。

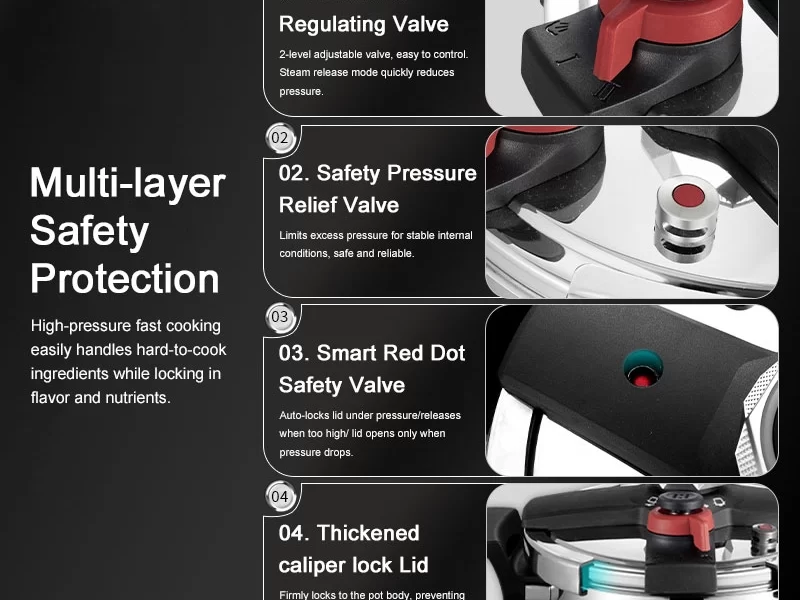

冗長設計: 高品質の圧力鍋 (例 リンクトン)には、安全性を高めるために一次および二次安全弁が装備されている。

ステータス表示

視覚的な手がかり: 安全弁の中には、圧力の状態を視覚的に表示するために、色分けされたマーカーやポップアップ式のデザイン(Fissler社のVitavitシステムなど)を採用しているものもある。

聴覚的な警告: ヒス音が鳴り続ける場合は、圧力が高すぎるため、熱の調整が必要です。

安全弁の4大タイプ

圧力鍋 圧力制御と安全性を達成するために、様々なタイプの安全弁を使用する。下の表は、主な種類とその利点、制限をまとめたものである。

| タイプ | 動作原理 | メリット | デメリット |

|---|---|---|---|

| 加重 | 圧力解放をコントロールするためにウェイトを使用 | シンプルな構造、低コスト | 手動による圧力調整が必要 |

| スプリング搭載 | スプリングの張力でバルブの動作を制御 | 高い応答性、正確さ | スプリングは疲労しやすく、老化しやすい |

| 可溶性プラグ | 低温合金が溶けて圧力を解放 | 絶対的な信頼性、機械的な故障なし | シングルユース、交換が必要 |

| スマート・エレクトリック | センサー+マイクロプロセッサー制御 | プログラム可能な圧力、自動調整 | 電気代が高い |

安全弁技術進化のマイルストーン

1930年代の初期のウェイトバルブから、2020年代の現代のIoT対応スマートバルブまで、安全弁の進化は大きな節目を迎えている。

1930s:第一世代ウェイト式安全弁(アルミ圧力鍋)。

1980s:スプリング式安全弁が普及し、精度が±5kPaに向上。

2000s: 複合安全システム(例:Liantongの4重圧力解放設計)。

2020s: IoTスマート安全弁(Wi-Fiアラート+自動電源オフ機能)。

革新的安全技術の展望

今後、安全弁技術は、厨房の安全性と作業効率を高めるため、よりインテリジェントで自動化されたソリューションを統合していくと予想される。

- セルフクリーニング・バルブ:超音波スケール除去技術(リンクトン2024コンセプトモデル)。

- 生体認証:指紋認証+チャイルドロックのダブル保険。

- 衛星接続:極端な過圧時に自動的に救難信号を送信(業務用モデル)。

ブランド安全弁技術の比較

以下の比較は、業務用厨房オペレーターが精度、信頼性、メンテナンスの利便性に基づいて最適な圧力鍋を選ぶのに役立つ。

| ブランド | 安全弁技術 | 応答精度 | 特集 |

|---|---|---|---|

| フィスラー | ビタビット定圧システム | ±2kPa | ビジュアル圧力インジケーター |

| リクトン | デュアルスプリング冗長設計 | ±3kPa | 目詰まり防止フィルター+着脱式クリーニング |

| インスタントポット | 電動ソレノイドバルブ | ±1kPa | APP圧力モニタリング |

| ツヴィリング | クールタッチ安全弁 | ±4kPa | バルブは触れても冷たいまま |

圧力鍋の安全弁 よくある質問 (FAQ)

Q1: 安全弁から食品残渣が吹き出るのは普通ですか?

答えてくれ: 異常。目詰まり防止フィルターの故障、または食品成分の過多を示します。直ちに使用を中止し、洗浄してください。

Q2:安全弁の交換頻度はどのくらいですか?

答えてくれ: スプリング式バルブは2~3年ごとに交換する必要がある。可溶性プラグは溶けるたびに交換する必要がある。

Q3: 安全弁は自分で分解できますか?

答えてくれ: 取り外し可能なデザイン(例えば、Liantongのツイストオフタイプ)に限る。ほとんどのブランドは工場でのメンテナンスを推奨している。

結論

安全弁は単なる部品ではなく、厨房の環境と作業者の両方を守る重要な装置です。圧力鍋を選ぶ際には、優先順位をつけましょう:

- 多重安全設計(一次弁と二次弁など)。

- 分解・洗浄が容易な構造(長期的なスケールの蓄積を回避)。

- ブランドのアフターセールス・サポート(部品供給の確保)。

として プロの圧力鍋メーカー, Linkton 高精度、安全で信頼性の高いマルチタイプの安全弁製品とカスタマイズされたサービスを提供し、ケータリングや商業厨房のお客様に安定した供給と技術サポートを提供することをお約束します。ようこそ お問い合わせ!