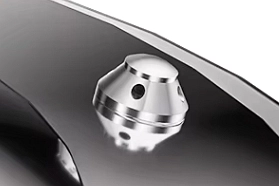

No mundo do panelas de pressão, o válvula reguladora de pressão é um dos aspectos mais importantes da segurança e do desempenho. Determina não só a qualidade da cozedura uniforme dos alimentos, mas também a segurança do funcionamento da panela a alta pressão.

Fabricante de panelas de pressão em aço inoxidável para fins comerciais, Linkton está bem ciente de que a engenharia de precisão da válvula de pressão afecta diretamente o desempenho da cozedura, a longevidade do produto e a segurança do utilizador. Este artigo irá explicar-lhe os princípios de funcionamento, as principais funções, os tipos e as sugestões de manutenção da válvula.

Funções principais da válvula reguladora de pressão

Regulação e controlo da pressão

Pressão de trabalho definida: A válvula mantém a pressão interna dentro de um intervalo predefinido (normalmente 50-100 kPa) através do seu próprio peso ou da tensão da mola.

Libertação automática da pressão: Quando a pressão ultrapassa o limite de segurança, a válvula levanta-se automaticamente para libertar o excesso de vapor.

Funcionamento estável: Através da ventilação intermitente, mantém um equilíbrio dinâmico de pressão para um desempenho de cozedura consistente.

Melhoria do desempenho na cozinha

Controlo da temperatura: À pressão definida, a válvula estabiliza a temperatura interna do vapor entre 100-121°C.

Eficiência de tempo: Os ambientes de alta pressão reduzem o tempo de cozedura até 70%.

Preservação de nutrientes: Os ciclos de cozedura mais curtos ajudam a reter as vitaminas e os minerais de forma mais eficaz.

Proteção de segurança

Prevenção de sobrepressão: Liberta a pressão antes de esta atingir um nível perigoso.

Sistema de segurança duplo: Funciona em coordenação com a válvula de segurança para formar um duplo mecanismo de proteção.

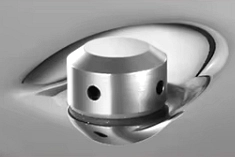

Três tipos principais de válvulas reguladoras de pressão

| Tipo | Princípio de funcionamento | Cenário de aplicação | Caraterísticas |

| Ponderado | Utiliza um contrapeso para controlar a pressão | Modelos tradicionais de fogões de sala | Estrutura simples/Ajuste manual necessário |

| SpringLoaded | Utiliza a tensão da mola para controlar a válvula | Modelos universais modernos | Pressão exacta/Longa vida útil |

| Magnético | Utiliza materiais magnéticos para controlar a posição da válvula | Panelas de pressão eléctricas | Resposta/Excelente selagem |

Especificações técnicas a conhecer

Pressão de trabalho: Normalmente gravado no corpo da válvula (por exemplo, 80 kPa).

Taxa de libertação de vapor: A quantidade de vapor libertado por minuto (g/min).

Ciclo de vida: As válvulas de alta qualidade (como as de mola da Linkton) ultrapassam os 100 000 ciclos.

Classe de precisão: Classe A ±3 kPa, Classe B ±5 kPa (de acordo com a norma nacional GB15066).

Diretrizes de instalação e utilização

Instalação correta

- Verificar se a sede da válvula está limpa e sem resíduos de alimentos.

- Instalar verticalmente para um funcionamento suave.

- O modelo da válvula deve sempre corresponder ao tipo de fogão - os diferentes modelos não são permutáveis.

Notas de utilização

- Manter a saída de ar desobstruída; evitar a imersão da válvula em espuma ou sopa.

- Durante o funcionamento, deve ouvir-se um som sibilante rítmico.

- Nunca adicionar pesos extra ou bloquear a válvula manualmente.

Resolução de problemas comuns

- Sem lançamento no Steam: Desligue imediatamente o aquecimento; deixe arrefecer e limpe a válvula.

- Libertação contínua de vapor: Baixar ligeiramente o lume.

- Salpicos de comida: Limpar a válvula e reduzir a quantidade de alimentos.

Guia de manutenção diária

Limpeza e conservação

- Lavar a válvula com água quente após cada utilização.

- Mergulhe semanalmente em vinagre branco para remover a acumulação de calcário.

- Verificar regularmente a flexibilidade das peças móveis.

Ciclo de substituição recomendado

Ponderado: 3-5 anos. Verificar o desgaste.

Com mola: 5-8 anos. Verificar a tensão da mola.

Magnético: 23 anos. Monitorizar a força magnética

Dicas de armazenamento

- Armazenar a válvula separadamente para evitar a deformação por pressão.

- Conservar num ambiente seco para evitar a ferrugem.

- Evitar o contacto com produtos químicos corrosivos.

Comparação de marcas

| Marca | Caraterísticas técnicas | Pressão de trabalho | Controlo da precisão |

| Liantong | Design de pressão de canal duplo | 80 kPa | ±2 kPa |

| Fissler | Micro-ajuste de pressão constante | 90 kPa | ±3 kPa |

| WMF | Estrutura tripla | 85 kPa | ±4 kPa |

| Genéricos | Regulação standard da pressão por mola | 70 kPa | Design de pressão de canal duplo |

Perguntas frequentes sobre a válvula reguladora de pressão

Q1: Porque é que devo substituir regularmente a válvula reguladora de pressão?

R: A utilização a longo prazo provoca a fadiga da mola e o envelhecimento do vedante, o que afecta a precisão e a segurança da pressão.

P2: Posso ajustar a pressão manualmente?

R: Nunca. As definições de pressão são calibradas com precisão; a modificação manual pode criar sérios riscos de segurança.

P3: Posso utilizar indistintamente válvulas de marcas diferentes?

R: Não. Os parâmetros e as dimensões da interface de cada marca são diferentes, o que os torna incompatíveis.

Inovações tecnológicas nas válvulas modernas

Controlo de pressão inteligente: Os sensores e os microprocessadores asseguram uma regulação precisa em tempo real.

Design de auto-limpeza: Evita o entupimento por resíduos alimentares.

Indicadores visuais: Apresenta os níveis de pressão em tempo real.

Monitorização sem fios: Liga-se através de Bluetooth a aplicações móveis para acompanhamento do estado.

Conclusão

O válvula reguladora de pressão pode ser pequena, mas a sua importância na panela de pressão a segurança e o desempenho não podem ser subestimados.

- Escolha sempre válvulas de alta precisão de fabricantes fiáveis.

- Efetuar inspecções e limpezas regulares.

- Siga todas as diretrizes de funcionamento para garantir uma utilização segura durante décadas.

Em LinktonCombinamos mais de 25 anos de experiência em panelas de pressão em aço inoxidável com engenharia avançada de válvulas para garantir um desempenho consistente, uma longa vida útil e a máxima segurança para o utilizador.

Fontes de dados:

- GB15066-2020 Norma nacional de segurança para panelas de pressão

- Relatório nacional de inspeção da qualidade das panelas de pressão

- Código internacional de segurança para recipientes sob pressão ASME BPVC