A válvula de segurança é o "coração" de um panela de pressãodiretamente relacionado com a segurança de utilização. De acordo com as estatísticas, 70% dos acidentes com panelas de pressão estão relacionados com falhas ou má utilização da válvula de segurança. Este artigo fornece uma análise aprofundada das funções da válvula de segurança da panela de pressão, princípios de funcionamento e dicas de manutenção para o ajudar a dominar totalmente este componente crítico.

Principais funções das válvulas de segurança para panelas de pressão

Regulação da pressão

Libertação automática da pressão: Quando a pressão da panela excede o valor nominal (normalmente 80-100kPa), a válvula abre-se automaticamente para libertar o vapor.

Manutenção da pressão: Mantém a pressão constante dentro de um intervalo seguro para garantir uma cozedura uniforme.

Proteção contra sobrepressão

Mecanismo anti-explosão: Actua como a última linha de defesa para libertar forçosamente a pressão quando a ventilação principal está bloqueada ou a pressão aumenta anormalmente.

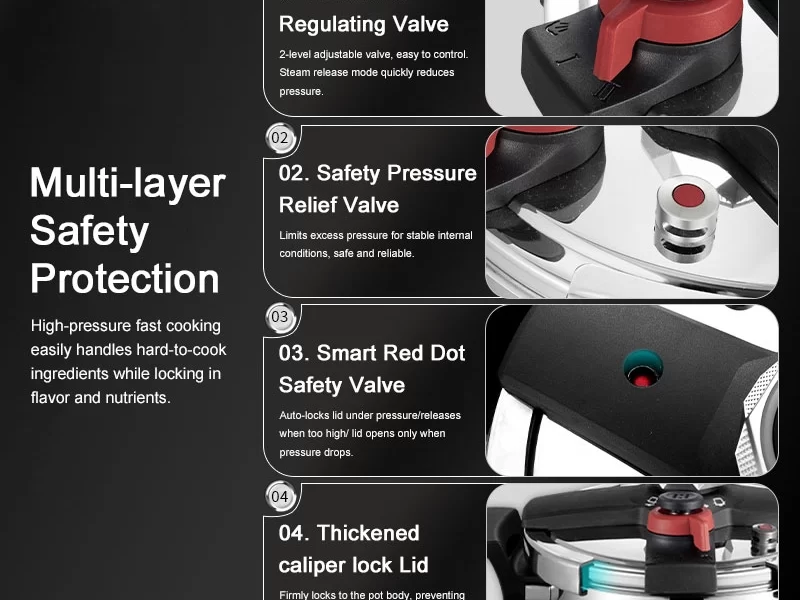

Conceção redundante: Panelas de pressão de alta qualidade (por exemplo, Linkton) estão equipados com válvulas de segurança primárias e secundárias para maior segurança.

Indicação de estado

Pistas visuais: Algumas válvulas de segurança possuem marcadores codificados por cores ou desenhos pop-up (por exemplo, o sistema Vitavit da Fissler) para indicar visualmente o estado da pressão.

Avisos sonoros: Um som sibilante contínuo indica uma pressão excessiva, exigindo um ajuste do aquecimento.

Quatro tipos principais de válvulas de segurança

Panelas de pressão utilizam diferentes tipos de válvulas de segurança para obter controlo de pressão e segurança. A tabela abaixo resume os principais tipos, as suas vantagens e limitações.

| Tipo | Princípio de funcionamento | Vantagens | Desvantagens |

|---|---|---|---|

| Ponderado | Utiliza um peso para controlar a libertação de pressão | Estrutura simples, baixo custo | Requer ajuste manual da pressão |

| Carregado por mola | Utiliza a tensão da mola para controlar o funcionamento da válvula | Altamente reativo, preciso | As molas são propensas à fadiga e ao envelhecimento |

| Tampão com fusível | A liga de baixa temperatura funde-se para libertar a pressão | Absolutamente fiável, sem falhas mecânicas | De utilização única, requer substituição |

| Elétrico inteligente | Sensor + controlo por microprocessador | Pressão programável, ajuste automático | Caro, depende da eletricidade |

Marcos na evolução da tecnologia das válvulas de segurança

A evolução das válvulas de segurança tem registado marcos significativos: desde as primeiras válvulas ponderadas, na década de 1930, até às modernas válvulas inteligentes com capacidade de IoT, na década de 2020.

1930s: Válvulas de segurança ponderadas de primeira geração (panelas de pressão de alumínio).

1980s: As válvulas de segurança com mola tornaram-se populares, com precisão melhorada para ±5kPa.

2000s: Sistemas de segurança compostos (por exemplo, o projeto de libertação de pressão quádrupla da Liantong).

2020s: Válvulas de segurança inteligentes IoT (alertas Wi-Fi + funções de desligamento automático).

Perspectivas das tecnologias de segurança inovadoras

Olhando para o futuro, espera-se que a tecnologia das válvulas de segurança integre soluções mais inteligentes e automatizadas para melhorar a segurança das cozinhas e a eficiência operacional.

- Válvulas de auto-limpeza: Tecnologia de descalcificação por ultra-sons (modelo concetual Linkton 2024).

- Reconhecimento biométrico: Ativação por impressão digital + duplo seguro de bloqueio para crianças.

- Conectividade por satélite: Envia automaticamente sinais de socorro em caso de sobrepressão extrema (modelos comerciais).

Comparação de tecnologias de válvulas de segurança de marca

A comparação abaixo ajuda os operadores de cozinhas comerciais a escolher a panela de pressão mais adequada com base na precisão, fiabilidade e facilidade de manutenção.

| Marca | Tecnologia de válvulas de segurança | Precisão de resposta | Caraterísticas especiais |

|---|---|---|---|

| Fissler | Sistema de pressão constante Vitavit | ±2kPa | Indicador visual de pressão |

| Likton | Design redundante de mola dupla | ±3kPa | Filtro à prova de obstrução + limpeza amovível |

| Panela Instantânea | Válvula solenoide eléctrica | ±1kPa | Monitorização da pressão APP |

| ZWILLING | Válvula de segurança Cool-Touch | ±4kPa | A válvula mantém-se fria ao toque |

Perguntas frequentes sobre a válvula de segurança da panela de pressão (FAQ)

Q1: É normal que saiam resíduos alimentares da válvula de segurança?

Resposta: Anormal. Indica uma falha no filtro à prova de entupimento ou excesso de ingredientes alimentares. Interromper imediatamente a utilização e limpar.

Q2: Com que frequência devem ser substituídas as válvulas de segurança?

Resposta: As válvulas com mola devem ser substituídas a cada 2-3 anos; os tampões fusíveis devem ser substituídos após cada fusão; os tipos eléctricos requerem manutenção de acordo com o manual.

Q3: Posso desmontar a válvula de segurança sozinho?

Resposta: Apenas para modelos amovíveis (por exemplo, o tipo twist-off da Liantong). A maioria das marcas recomenda a manutenção na fábrica.

Conclusão:

As válvulas de segurança são mais do que simples componentes; são dispositivos essenciais que protegem tanto o ambiente da cozinha como os operadores. Ao escolher uma panela de pressão, dê prioridade:

- Conceção de segurança multi-redundante (por exemplo, válvulas primárias e secundárias).

- Estrutura de fácil desmontagem e limpeza (evita a acumulação de incrustações a longo prazo).

- Apoio pós-venda da marca (garantir a disponibilidade de peças).

Como fabricante profissional de panelas de pressão, Linkton fornece produtos de válvulas de segurança multi-tipo de alta precisão, seguros e fiáveis e serviços personalizados, e está empenhada em fornecer um fornecimento estável e apoio técnico aos clientes de catering e de cozinhas comerciais. Bem-vindo ao contactar-nos!