En tant que premier factory specializing in stainless steel pressure cooker manufacturing, we adhere to a rigorous production and Quality Control (QC) system. Our commitment ensures that every unit meets stringent international standards. This guide provides a systematic overview of the Linkton manufacturing journey—from raw material selection to final dispatch—highlighting our manufacturing excellence and quality benchmarks for our global partners.

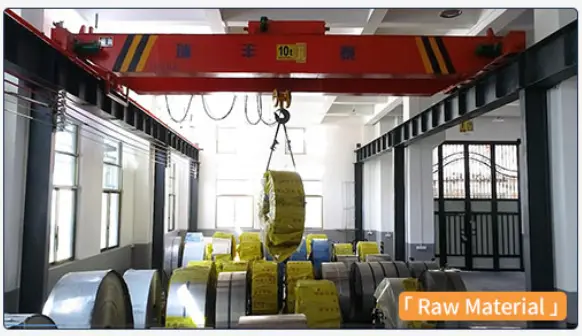

Step 1: Incoming Quality Control (IQC)

Quality begins at the source. Every batch of SUS 304/316 stainless steel coils undergoes strict Incoming Quality Control (IQC).https://www.linktonkitchen.com/

- Chemical Analysis: Utilizing advanced spectrometers to verify Chromium (Cr) and Nickel (Ni) content.

- Physical Testing: We inspect steel thickness and surface finish before the Blanking process, where steel coils are cut into precise circular discs.

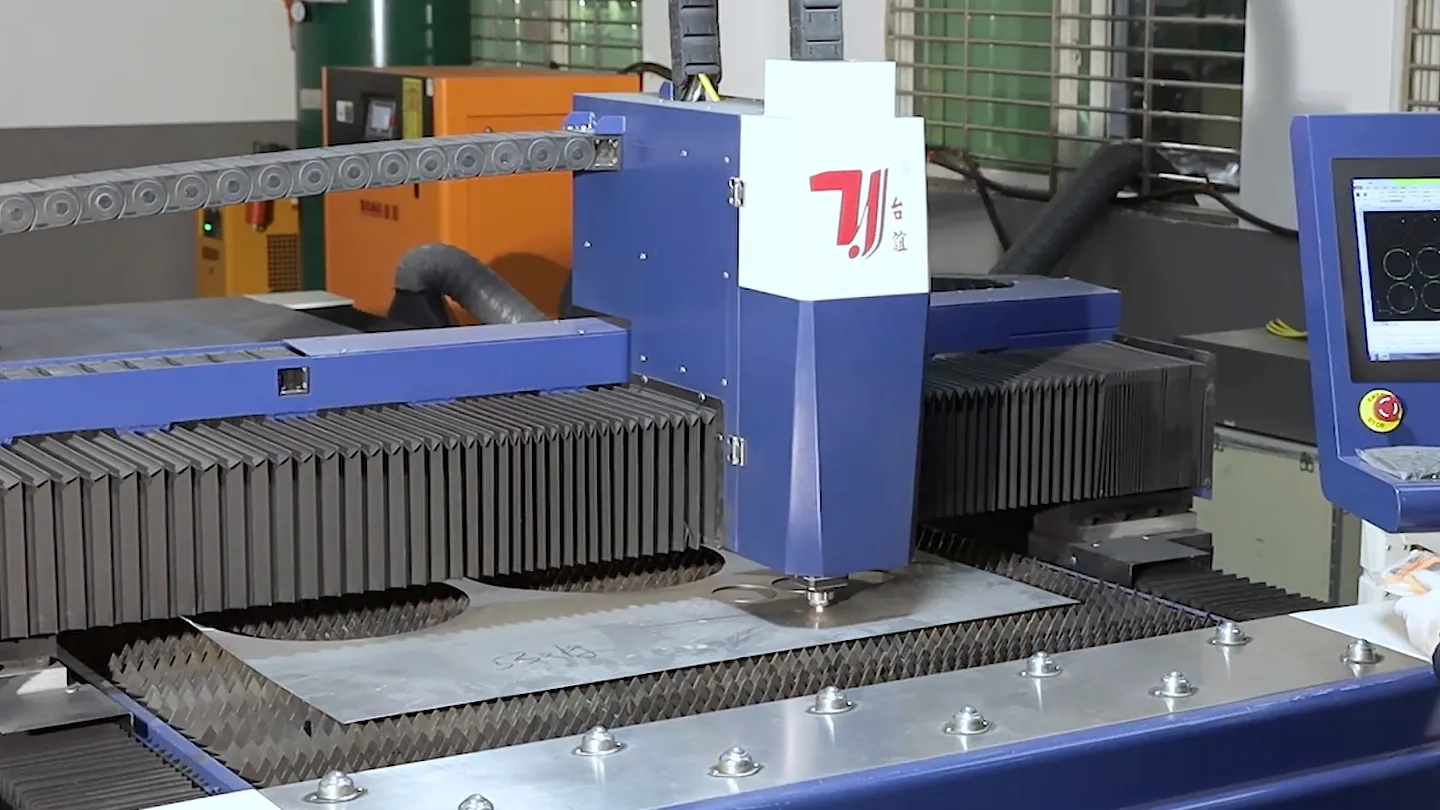

Step 2: Body Forming & Deep Drawing

This stage defines the structural integrity of the pressure cooker.

- Deep Drawing: Using high-tonnage hydraulic presses, we transform steel discs into a seamless, one-piece pot body.

- Trimming & Beading: Excess edges are removed, and the rim is reinforced to ensure an airtight seal with the lid.

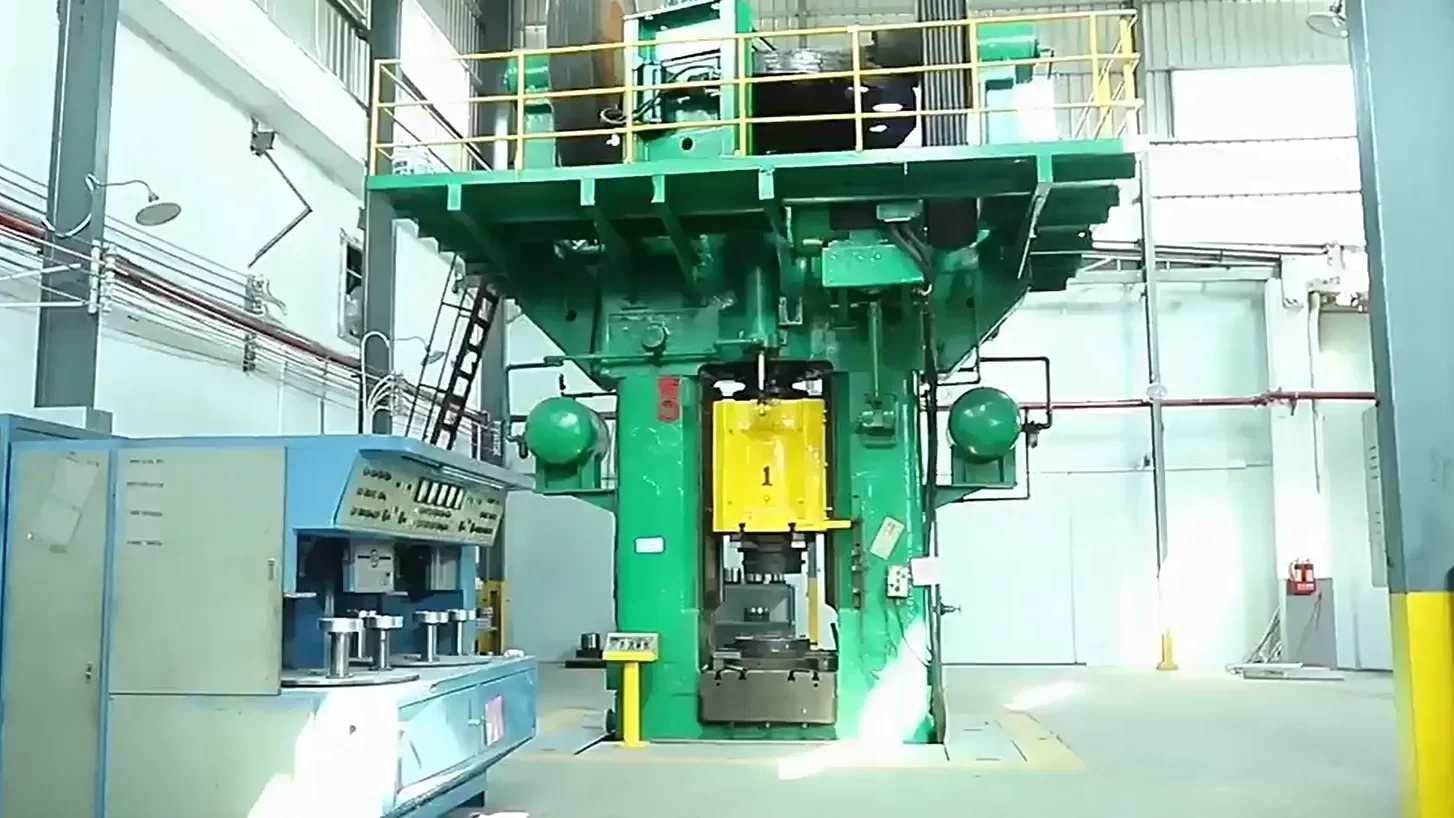

Step 3: Advanced Impact Bonding (Multi-Ply Base)

To ensure induction compatibility and superior thermal efficiency:

- High-Pressure Fusion: Under 2,500 tons of pressure, layers of aluminum and 430 stainless steel are fused to the base. This “Impact Bonding” prevents the bottom from warping or detaching after years of high-heat cycles.

- Polyvalence : We offer 3-ply and 5-ply composite base options to suit different market needs.

Step 4: Surface Finishing & Customization

- Multi-Stage Polishing: Every unit undergoes automatic and manual polishing to achieve a Mirror Finish ou Satin Finish.

- Laser Branding: Precision laser engraving for OEM brand logos.

- Ultrasonic Cleaning: A thorough ultrasonic bath removes all industrial oils and polishing residues, ensuring food-grade cleanliness.

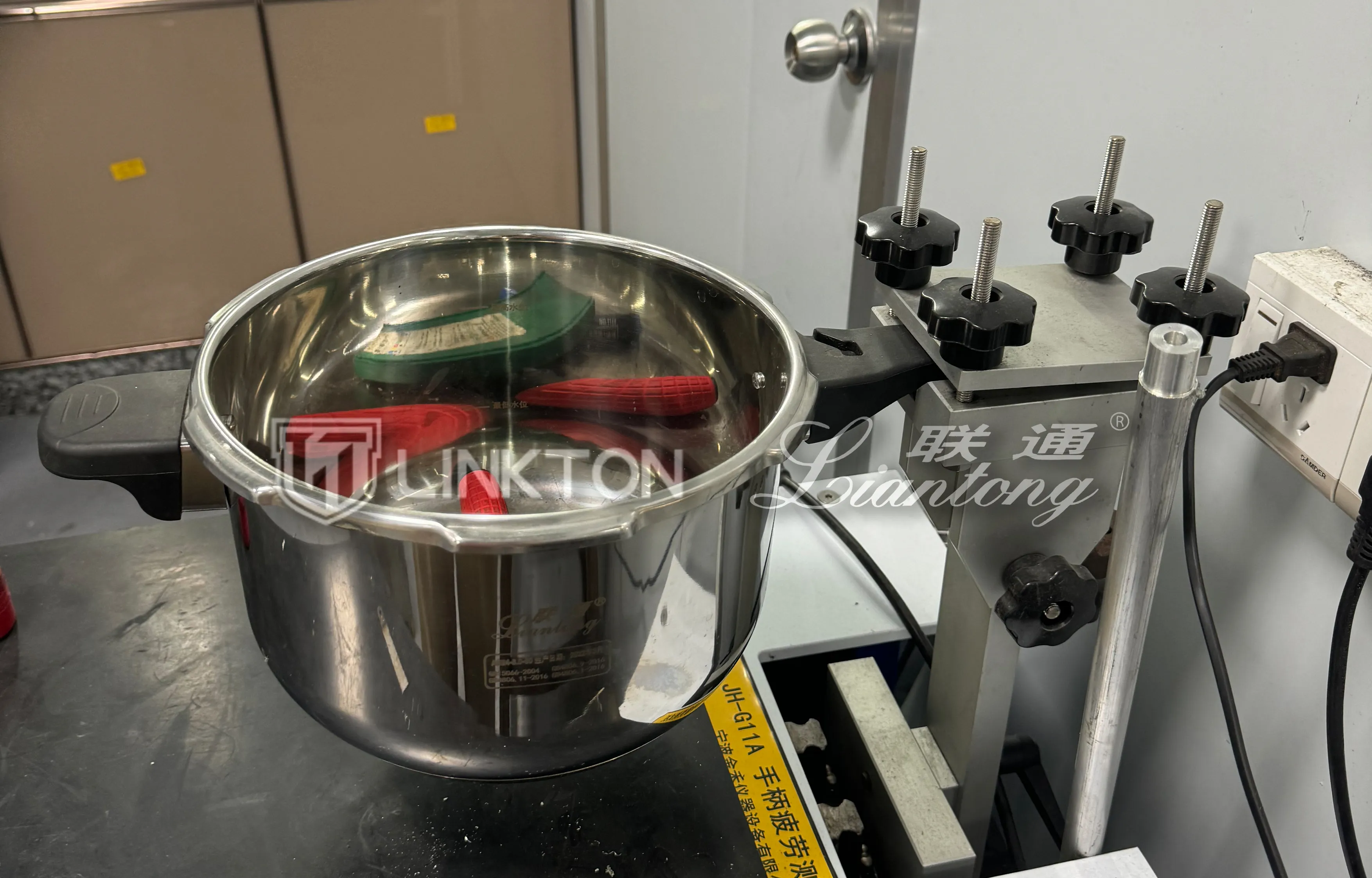

Step 5: The Linkton Quality Control System (The Heart of Production)

A three-tier inspection process governs our manufacturing:

1. In-Process Quality Control (IPQC)

- Safety Valve Reliability: Testing the exact pressure threshold at which valves release steam.

- Pneumatic Pressure Test: Each finished unit is pressurized to ensure the body and lid withstand preset working pressures without deformation.

- Structural Integrity: Technicians monitor riveting precision and handle attachment strength.

- Functional Check: Verification of smooth valve open/close operations.

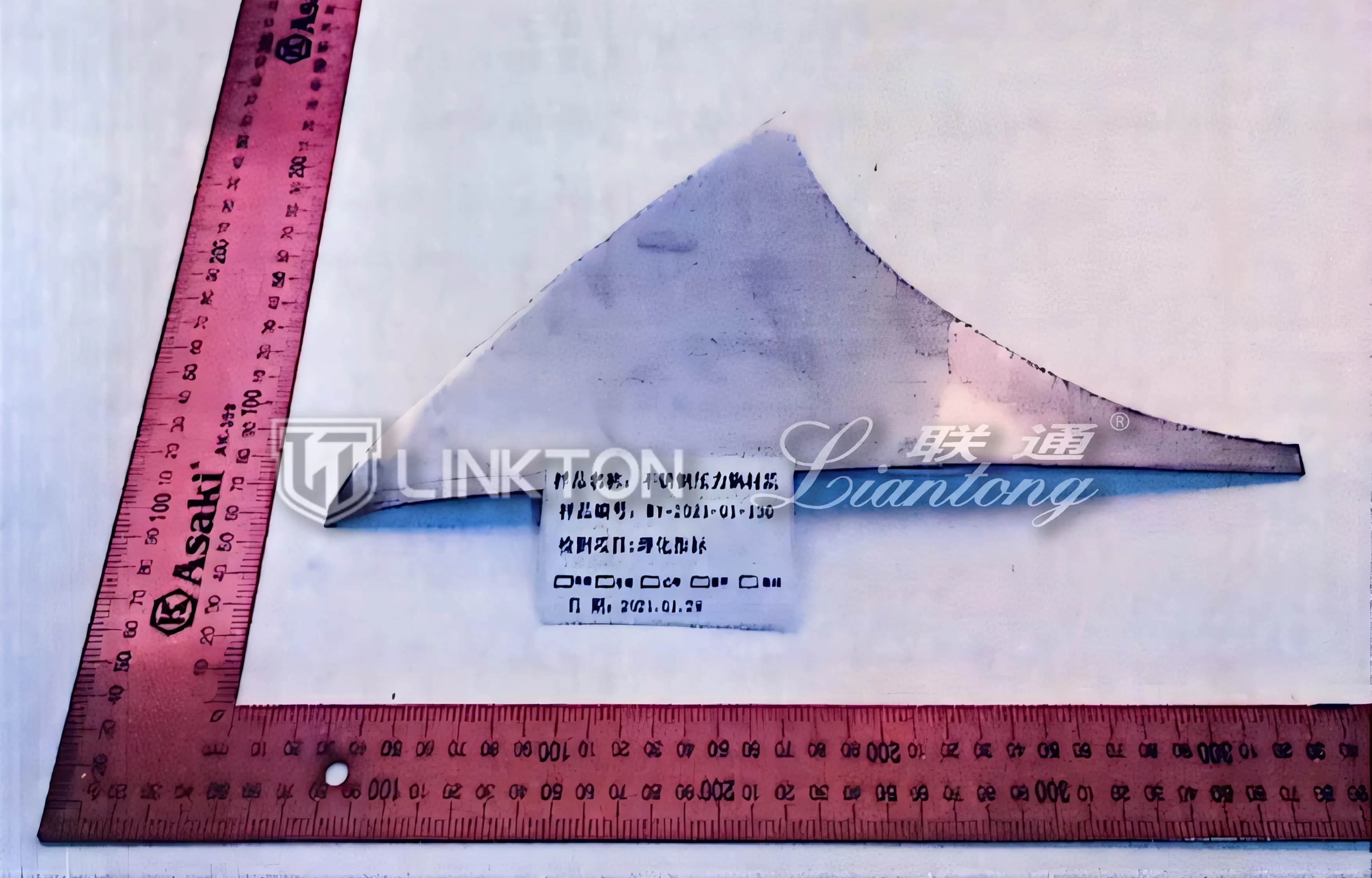

2. Final Quality Control (FQC) & Laboratory Testing

Before packaging, random samples undergo rigorous functional and destructive testing:

- Handle Durability: Testing tolerances and thermal resistance to ensure long-term ergonomic safety.

- Gasket/Sealing Ring Stress Test: Sealing rings are submerged in acidic or oily water for 72 hours to verify material stability and leak-proof performance.

- Real-World Performance: Simulating home cooking scenarios to verify heating efficiency and heat distribution.

- Salt Spray Test: Ensuring 100% corrosion resistance in humid or coastal environments.

3. Outgoing Quality Control (OQC)

Before the container is sealed, a final inspection is conducted in accordance with AQL (Acceptance Quality Limit) standards, covering packaging integrity, manual accuracy, and aesthetic perfection.

Quality & Certification Support

Our production adheres to international management systems. We provide comprehensive documentation to support your market entry:

- ISO 9001 Quality Management.

- LFGB / FDA (Food Contact Safety).

- Coordination with Third-Party Inspections (SGS, TUV, BV) as per client requirements.

Conclusion: Stable Manufacturing for Long-term Partnership

From raw material to the final box, every step impacts the safety, durability, and user experience of a pressure cooker. Through standardized workflows and rigorous testing, Linkton ensures every autocuiseur en acier inoxydable meets the high-volume and high-quality demands of the B2B market.